Imagine a world where time isn’t just a concept but a mesmerizing mechanical masterpiece. The Mechanics of a Gear Clock will take you on a thrilling journey into this enchanting realm, where gears intertwine, each serving a unique purpose to keep time in perfect harmony. From the elegant rotation of the hour hand to the intricate orchestration of the minute and second hands, every detail of a gear clock is meticulously crafted to create a symphony of precision. Join us as we unravel the secrets behind this ingenious invention and discover the captivating mechanics that make a gear clock truly timeless.

Introduction to Gear Clocks

Gear clocks are fascinating timekeeping devices that have been used for centuries. They rely on the intricate interplay of various mechanical components to accurately measure and display time. In this article, we will explore the definition and function of gear clocks, as well as delve into their historical background.

Definition and Function

A gear clock is a type of clock that utilizes a set of gears to regulate the movement of its hands or display. These gears are interconnected in a specific arrangement, known as a gear train. As the gears rotate, they transfer energy from a power source to various other components, resulting in the movement of the clock’s hands. In this way, gear clocks provide us with a visual representation of the passage of time.

Historical Background

The concept of gear clocks dates back to ancient times, with early versions believed to have been developed by the ancient Greeks and Egyptians. However, it wasn’t until the Middle Ages that gear clocks became more sophisticated and complex. The invention of the verge escapement mechanism in the 14th century revolutionized clockmaking and paved the way for the development of more accurate and dependable gear clocks. Since then, gear clocks have undergone many advancements and variations, making them an integral part of human history.

Components of a Gear Clock

To better understand the mechanics of a gear clock, let’s take a closer look at its key components.

Gear Train

The gear train is the heart of a gear clock. It consists of a series of gears with different sizes and numbers of teeth. Each gear is connected to another gear in a sequential manner, allowing the transfer of energy from the power source to the other components of the clock. The ratio of teeth on the gears determines the speed at which the hands of the clock move, and thus, the accuracy of its timekeeping.

Mainspring

The mainspring is a coiled metal ribbon that stores potential energy when wound. It is responsible for powering the gear train and keeping the clock running. When the mainspring is wound, it releases its stored energy gradually, which in turn, drives the rotation of the gear train. The length and strength of the mainspring play a crucial role in determining the duration of the clock’s operation.

Escapement Mechanism

The escapement mechanism is a key component that regulates the flow of energy from the mainspring to the gear train. It prevents the gears from rotating freely and controls their movement in a controlled and calibrated manner. The escapement mechanism consists of various levers, pallets, and an escape wheel that work together to ensure the constant and uniform movement of the hands.

Pendulum

Some gear clocks, particularly older designs, incorporate a pendulum as a timekeeping regulator. The pendulum swings back and forth, driven by the energy from the gear train. Its movement is carefully calibrated, allowing the clock to maintain precise timekeeping. The length of the pendulum’s swing determines the rate at which the clock operates, with longer swings resulting in slower timekeeping and vice versa.

Working Principle

Now that we have examined the components of a gear clock, let’s delve into its working principle.

Power Transmission

The working principle of a gear clock revolves around the transmission of power from the mainspring to the gear train. When the mainspring is wound, it stores potential energy in the form of tension within its coiled structure. As the mainspring unwinds, it releases this energy, which is transferred to the first gear in the gear train. The rotation of this gear then drives the rotation of subsequent gears, ultimately resulting in the movement of the clock’s hands.

Escapement Action

The escapement mechanism is responsible for converting the rotational energy from the gear train into a rhythmic back-and-forth motion. This is achieved through the interaction between the pallets and the escape wheel. As the gears rotate, the escape wheel catches and releases the pallets, allowing the gears to move in small increments and creating the characteristic ticking sound associated with gear clocks. This escapement action ensures the consistent and even movement of the clock’s hands.

Types of Gear Clocks

Gear clocks can be broadly classified into three main types based on their power source.

Weight-Driven Gear Clocks

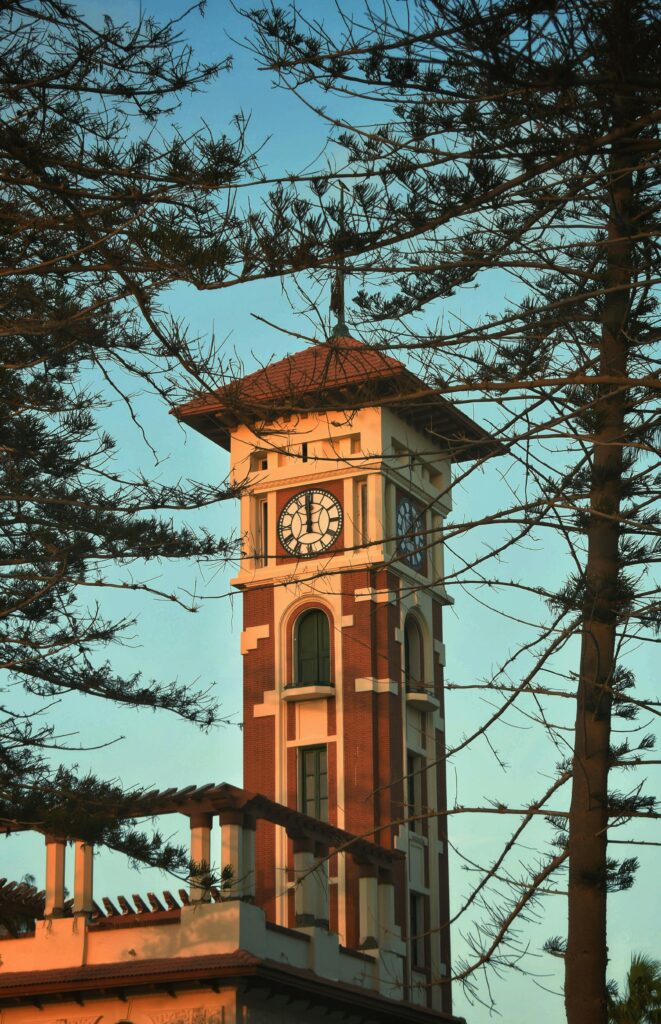

In weight-driven gear clocks, the power is provided by weights that are suspended from pulleys or chains. As the weights descend, they drive the rotation of the gears, keeping the clock running. These clocks are often found in buildings and public spaces due to their large size and heavy weight. Their intricate design and visible weight system add an aesthetic appeal to their functional purpose.

Spring-Driven Gear Clocks

Spring-driven gear clocks, as the name suggests, use a coiled spring as their power source. When the spring is wound, it stores potential energy, which is gradually released as the clock operates. These clocks are typically smaller and more portable compared to weight-driven clocks. They are often used as tabletop or mantle clocks and are popular for their elegant and compact designs.

Electric Gear Clocks

Electric gear clocks rely on an electrical power source, such as a battery or a mains connection. They utilize an electric motor to drive the gear train, eliminating the need for winding or the use of weights. Electric gear clocks offer convenience and accuracy, as they often feature quartz movements that guarantee precise timekeeping. These clocks can be found in both traditional and modern designs, catering to various aesthetic preferences.

Design Considerations

When designing a gear clock, several factors need to be taken into account to ensure optimal performance and visual appeal. Let’s explore some of these design considerations.

Gear Ratios

The gear ratios play a crucial role in determining the accuracy of a gear clock. By adjusting the number of teeth on each gear, clockmakers can control the speed at which the clock’s hands move. Achieving the desired gear ratios requires careful calculations and planning to ensure precise timekeeping.

Teeth Profiles

The shape and profile of the gear teeth also play a significant role in the smooth operation of a gear clock. Different teeth profiles, such as involute or cycloidal, can affect the efficiency, noise level, and overall performance of the clock. The choice of teeth profile depends on the specific requirements and design goals of the clockmaker.

Material Selection

The selection of materials for the components of a gear clock is essential for its durability and longevity. Clockmakers often choose metals such as brass or steel for the gears, escapement mechanism, and other critical parts due to their strength and resistance to wear. Additionally, wooden parts, such as the clock case, can provide an appealing aesthetic and add warmth to the overall design.

Size and Weight

The size and weight of a gear clock are important considerations that can impact its functionality and practicality. Larger clock mechanisms may require a more substantial and stable frame to support their weight and ensure smooth operation. The size of the clock hands and numerals should also be proportionate to the overall dimensions of the clock for clear visibility and readability.

Assembling a Gear Clock

Assembling a gear clock requires precision and attention to detail. Here’s an overview of the tools and equipment you will need, as well as a step-by-step process to guide you through the assembly.

Tools and Equipment

- Screwdrivers

- Pliers

- Tweezers

- Wrenches

- Lubricants

- Calipers

- Mallet

Step-by-Step Process

- Start by organizing all the components and ensuring that you have the necessary tools at hand.

- Carefully read the instructions or schematics provided with the gear clock kit.

- Begin by attaching the gear train to the mainframe, following the specified order and alignment.

- Install the mainspring and wind it according to the instructions, ensuring it is securely in place.

- Attach the escapement mechanism to the gear train, ensuring smooth movement and proper engagement between the pallets and escape wheel.

- If the clock incorporates a pendulum, install it carefully, ensuring proper suspension and regulation.

- Double-check all connections, ensuring that the gears rotate freely and smoothly.

- Test the clock by winding the mainspring and observing the movement of the hands.

- Make any necessary adjustments to ensure proper timekeeping and precise movement.

- Once satisfied with the assembly and functionality, secure all components in place and affix the clock case or housing.

- Give the clock a final test run and enjoy the satisfaction of your completed gear clock.

Troubleshooting

If you encounter any issues during the assembly or operation of your gear clock, don’t panic. Here are some common troubleshooting tips:

- If the clock hands are not moving, check the mainspring tension or the gear train alignment.

- If the clock is running too fast or slow, adjust the pendulum length or check the gear ratios.

- If the clock is making excessive noise, ensure proper lubrication of the gears and other moving parts.

- If any components are damaged or worn, consider replacing them to improve the performance and longevity of the clock.

Maintenance and Repair

Proper maintenance and occasional repair are essential to ensure the longevity and accuracy of your gear clock. Here are some key areas to focus on:

Cleaning and Lubrication

Regular cleaning and lubrication of the gears and other moving parts will help maintain smooth operation and prevent excessive wear. Use a soft brush or cloth to remove dust and dirt, and apply a suitable clock oil or lubricant as recommended by the manufacturer.

Adjusting Timekeeping

Over time, the accuracy of a gear clock may drift, necessitating adjustments to its timekeeping. This can be done by regulating the pendulum length or making minor changes to the gear train’s gear ratios. Consult the clock’s instructions or seek professional assistance to ensure precise timekeeping.

Replacing Worn Parts

If any components of your gear clock become worn or damaged, it is important to replace them promptly. This may include worn gears, broken pallets, or damaged springs. Ensure that you source high-quality replacement parts to maintain the clock’s functionality and accuracy.

Advantages and Disadvantages

Gear clocks offer several advantages and disadvantages compared to other timekeeping devices. Let’s explore some of them:

Advantages of Gear Clocks

- Mechanical Charm: Gear clocks provide a sense of mechanical craftsmanship and nostalgia, drawing admiration for their intricate design and craftsmanship.

- Visual Appeal: The moving gears of a gear clock create a mesmerizing visual display, enhancing any space with their unique aesthetic appeal.

- Precise Timekeeping: Well-constructed gear clocks can offer accurate and consistent timekeeping, often rivaling the precision of electronic timepieces.

- Longevity: When properly maintained, gear clocks can last for generations, becoming cherished heirlooms with sentimental value.

Disadvantages of Gear Clocks

- Need for Regular Maintenance: Gear clocks require periodic cleaning, lubrication, and adjustments to ensure their optimal performance, which may be seen as a drawback for those seeking a low-maintenance timekeeping solution.

- Audible Ticking Sound: Some people may find the ticking sound of a gear clock to be bothersome, particularly in quiet environments such as bedrooms.

- Fragility: The intricate mechanisms of gear clocks can be delicate, making them more prone to damage if mishandled or dropped.

- Complexity: Assembling or repairing a gear clock may require specialized knowledge and tools, making it less accessible to those without prior experience or expertise.

Popular Gear Clock Brands

Several brands have made a name for themselves in the world of gear clocks. Here are a few notable ones:

Brand A

Brand A is renowned for its elegant and classic designs, often incorporating intricate wooden carvings and polished brass components. Their gear clocks are highly sought after by collectors and enthusiasts alike, showcasing the timeless beauty of mechanical timepieces.

Brand B

Brand B, on the other hand, is known for pushing the boundaries of design and innovation. They combine modern materials and techniques with traditional gear clock mechanisms, creating contemporary timepieces that blend functionality with artistic expression.

Brand C

Brand C focuses on producing gear clocks that offer superior timekeeping accuracy. Their meticulous attention to detail and precision engineering result in high-performance clocks that cater to those who prioritize precise timekeeping above all else.

Conclusion

In conclusion, gear clocks are marvels of mechanical engineering, providing us with a unique and visually captivating way to measure time. From the interplay of gears in the gear train to the intricate escapement action, these timepieces showcase the ingenuity and craftsmanship of clockmakers throughout history. Whether you appreciate their mechanical charm or value their accurate timekeeping, gear clocks continue to captivate and inspire us with their precision and beauty.